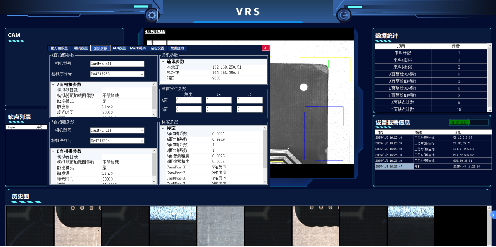

PCB online appearance inspection (VRS)

Equipment Purpose:

-Adopt self-developed AI algorithm system to realize automatic defect re-judgment and automatic sorting.

Equipment Introduction:

-Use a high-precision servo motion control platform to control the imaging system to acquire images stably and quickly;

-Through software architecture design, one server can be connected to multiple VRS automatic sorting machines.

Equipment features:

-VRS re-inspection: one person controls 4 units, reducing manpower by 75%;

-Large model with high computing power improves detection efficiency, with detection time ≤100ms;

-Use AI to improve detection reliability, filtering out 95% of false positives;

-Data statistical analysis.

Equipment parameters | |

Defect recognition rate | ≥95% |

Plate thickness | 0.5-3.2mm (including copper) |

Detection speed | 700mm/S (adjustable) |

AI model updates | Data sharing, one-click model training and deployment, fast iteration |

Repeatability | ±0.01mm |

Detection accuracy | 1.8mil line width |

Capacity | ≥6 tablets/min |