- Coated CCD detection system

- Roller press CCD detection system

- Roller Slitting Machine CCD Detection System/Labeling Machine

- Pole slice CCD detection system

- Independent wide CCD re-inspection machine

- Tab forming equipment CCD system

- Electrode burr detection

- Power battery winding machine CCD detection system

- Cutting and stacking machine CCD detection system

- Power Bare Cell Appearance Inspection Machine

- Power battery casing equipment/pre-spot welding

- Power battery top cover welding inspection machine

- Power battery sealing nail detection system

- Inspection of the front six sides of the blue film of the power battery pack

- Power battery aluminum shell, blue film appearance inspection machine

- Finished battery appearance inspection machine

- Power battery connector welding detection system

- Blade Battery Measurement Dimension Measuring Machine

- Power battery module Busbar testing machine

- Power battery module size detection

- Small power battery automatic FT test and air tightness testing machine

- Copper foil appearance inspection

- Aluminum foil appearance inspection

- Diaphragm appearance inspection

- Aluminum plastic film appearance inspection

- Visual inspection of cylindrical aluminum shell

- Appearance inspection of square aluminum shell

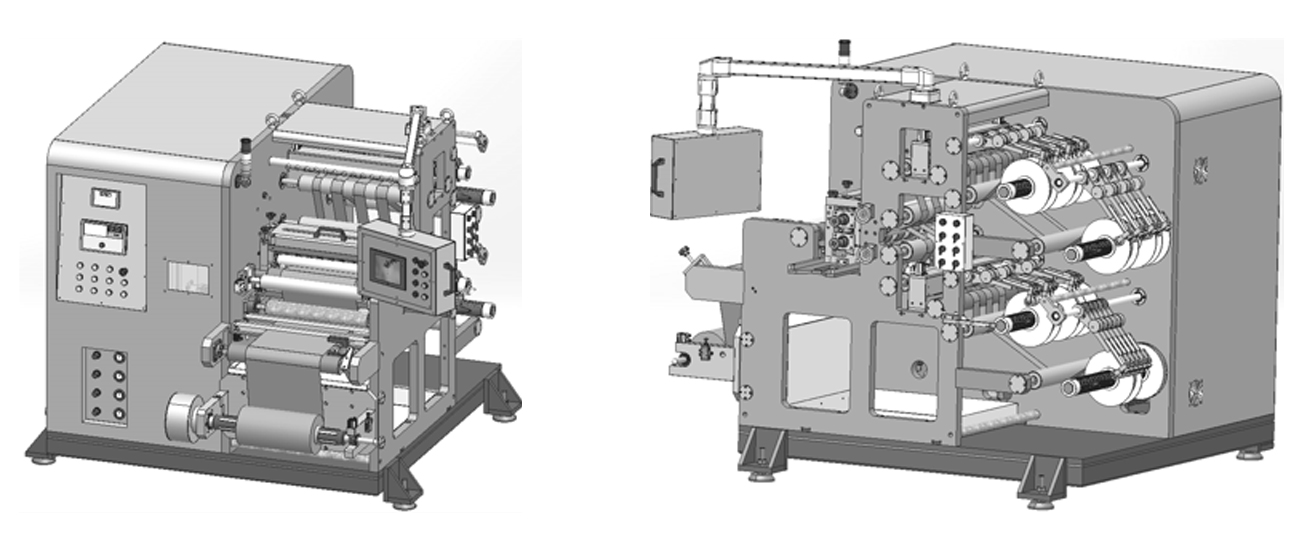

Pole slice CCD detection system

Name | Parameter |

Detection speed: | ≤120m/min |

Detection width: | 200mm-950mm |

Resolution: | 0.1mm/pix |

Dimensional detection accuracy: | ±0.1mm |

Defect Detection Accuracy: | 0.5mm*0.5mm (compared to standard film board) |

Detect the number of single-sided strips: | ≤32 items |

Overkill/missing rate: | Missed judgment rate ≤ 0.1%, false positive rate ≤ 0.5% |

The gray scale deviation of defects and coating film needs to meet ≥30 | |

Test content: | |

1) Width: | Full width, AB surface coating width, blank width, ceramic width |

2) Length: | Station measuring length |

3) Defect detection: | Dirt, surface damage, scratches, streaks, bubbles, leaking metal. |

Applicable process: | |

Process: | Continuous coating, striped coating, intermittent coating and intermittent striped coating, tabs in the middle, double film length, etc. |