- Coated CCD detection system

- Roller press CCD detection system

- Roller Slitting Machine CCD Detection System/Labeling Machine

- Pole slice CCD detection system

- Independent wide CCD re-inspection machine

- Tab forming equipment CCD system

- Electrode burr detection

- Power battery winding machine CCD detection system

- Cutting and stacking machine CCD detection system

- Power Bare Cell Appearance Inspection Machine

- Power battery casing equipment/pre-spot welding

- Power battery top cover welding inspection machine

- Power battery sealing nail detection system

- Inspection of the front six sides of the blue film of the power battery pack

- Power battery aluminum shell, blue film appearance inspection machine

- Finished battery appearance inspection machine

- Power battery connector welding detection system

- Blade Battery Measurement Dimension Measuring Machine

- Power battery module Busbar testing machine

- Power battery module size detection

- Small power battery automatic FT test and air tightness testing machine

- Copper foil appearance inspection

- Aluminum foil appearance inspection

- Diaphragm appearance inspection

- Aluminum plastic film appearance inspection

- Visual inspection of cylindrical aluminum shell

- Appearance inspection of square aluminum shell

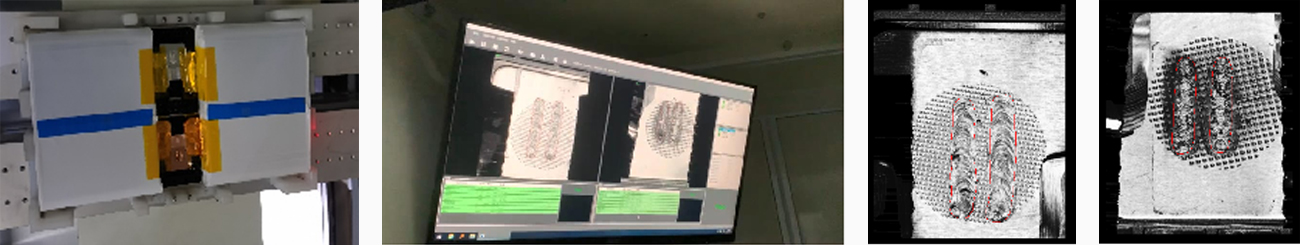

Power battery connector welding detection system

Feature

· Online real-time detection, embedded in the existing pack production line;

· 3D+2D dual information synthesis, various welding defects and size inspection;

· 3D point cloud engine standard and training, using AI artificial intelligence algorithm for all-round 360-degree appearance inspection without dead angle;

Effect

· Weld spacing: accuracy ±0.03mm

· The length of the whole welding print: accuracy ± 0.03mm

· Melting width: accuracy ±0.03mm

· Breaking point: accuracy ≥ 99.95%

· Lack of welding and missing welding: accuracy rate ≥99.95%

· Defective products are misjudged as good products: 0%

· Misjudgment of a good product as a defective product: ≤0.1%