- Coated CCD detection system

- Roller press CCD detection system

- Roller Slitting Machine CCD Detection System/Labeling Machine

- Pole slice CCD detection system

- Independent wide CCD re-inspection machine

- Tab forming equipment CCD system

- Electrode burr detection

- Power battery winding machine CCD detection system

- Cutting and stacking machine CCD detection system

- Power Bare Cell Appearance Inspection Machine

- Power battery casing equipment/pre-spot welding

- Power battery top cover welding inspection machine

- Power battery sealing nail detection system

- Inspection of the front six sides of the blue film of the power battery pack

- Power battery aluminum shell, blue film appearance inspection machine

- Finished battery appearance inspection machine

- Power battery connector welding detection system

- Blade Battery Measurement Dimension Measuring Machine

- Power battery module Busbar testing machine

- Power battery module size detection

- Small power battery automatic FT test and air tightness testing machine

- Copper foil appearance inspection

- Aluminum foil appearance inspection

- Diaphragm appearance inspection

- Aluminum plastic film appearance inspection

- Visual inspection of cylindrical aluminum shell

- Appearance inspection of square aluminum shell

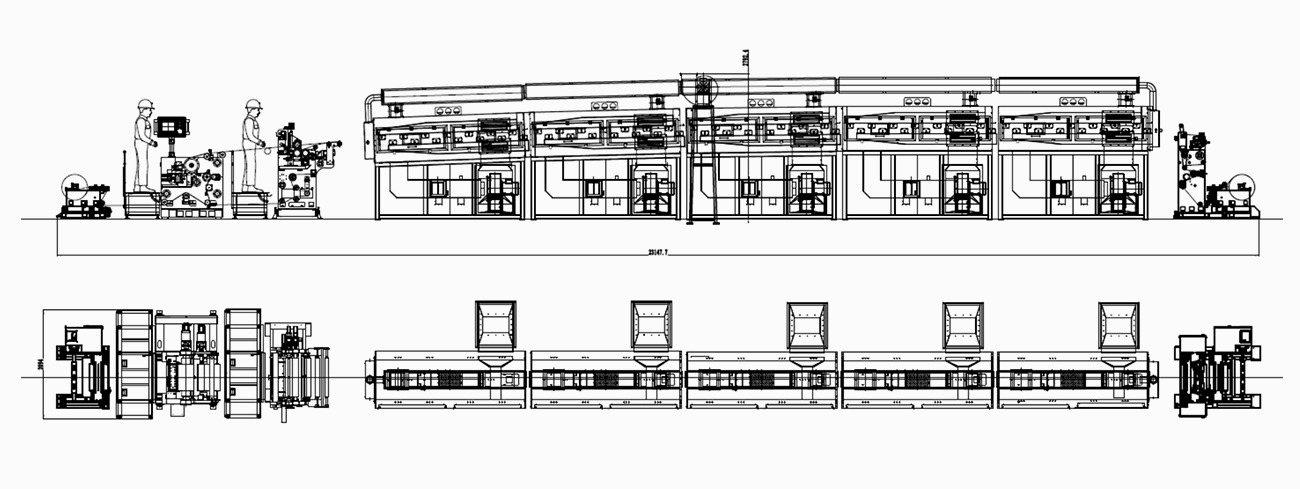

Coated CCD detection system

Name | Parameter |

Detection speed: | ≤120m/min |

Detection width: | 700mm-1550mm |

Resolution: | 0.024mm/pix (horizontal); 0.048mm/pulse (vertical) |

Dimensional detection accuracy: | ±0.1mm |

Defect Detection Accuracy: | 0.5mm*0.5mm |

Detect the number of single-sided strips: | ≤4 pieces |

Overkill/missing rate: | Misjudgment: 0%, Misjudgment: ≤0.1% GRR≤10% (standard tolerance is ±0.6mm) |

The gray scale deviation of defects and coating film needs to meet ≥30 | |

Equipment Dimensions: | Compatible device manufacturers |

Inspection content: width, alignment, defects | |

1) Coating width: | Wet material, dry material (full width, AB surface coating width, blank width, ceramic width) |

2) Alignment: | Measure the alignment of the AB side at the station of the A side dry material and the B side wet material. |

3) Defect detection: | Dirt, surface damage, scratches, streaks, bubbles, leaking metal. |

Applicable process: | Extrusion, transfer, gravure |

1) Coating process: | Continuous coating, stripe coating, intermittent coating and intermittent stripe coating. |

2) Product process: | Compatible with AT9 and concave board |