- Coated CCD detection system

- Roller press CCD detection system

- Roller Slitting Machine CCD Detection System/Labeling Machine

- Pole slice CCD detection system

- Power battery connector welding detection system iis7站长之家

- Tab forming equipment CCD system

- Electrode burr detection

- Power battery winding machine CCD detection system

- Cutting and stacking machine CCD detection system

- Power Bare Cell Appearance Inspection Machine

- Power battery casing equipment/pre-spot welding

- Power battery top cover welding inspection machine

- Power battery sealing nail detection system

- Inspection of the front six sides of the blue film of the power battery pack

- Power battery aluminum shell, blue film appearance inspection machine

- Finished battery appearance inspection machine

- Power battery connector welding detection system

- Blade Battery Measurement Dimension Measuring Machine

- Power battery module Busbar testing machine

- Power battery module size detection

- Small power battery automatic FT test and air tightness testing machine

- Copper foil appearance inspection

- Aluminum foil appearance inspection

- Diaphragm appearance inspection

- Aluminum plastic film appearance inspection

- Visual inspection of cylindrical aluminum shell

- Appearance inspection of square aluminum shell

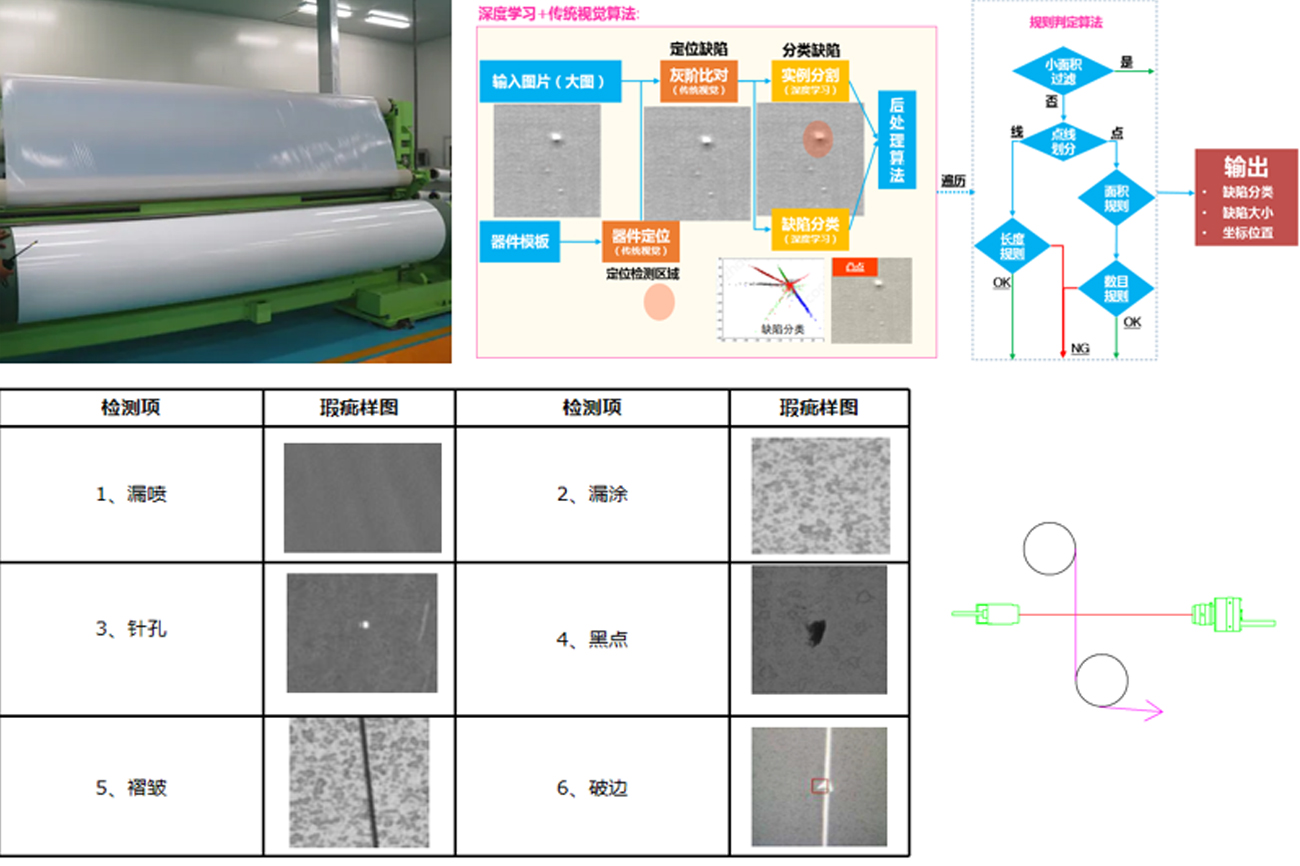

Diaphragm appearance inspection

Name | Parameter |

Detection speed: | 80-150m/min |

Product Range: | Diaphragm |

Resolution: | Line scan: 0.05 (horizontal) * 0.05 (vertical) mm/pix; |

Detection accuracy: | 0.05mm² |

Overkill/missing rate: | Omission rate: 0%, overkill rate: ≤0.1% |

Equipment Dimensions: | Embedded in original equipment (custom) |

Applicable process: | Separator coating, slitting |

Test content: | Missing spray, missing coating, pinholes, bright spots, black spots, wrinkles, broken edges |